SAP Digital Manufacturing

Unlock the full potential of Industry 4.0 with D4M Experts

Revolutionize your smart manufacturing operations with SAP Digital Manufacturing (DM)

Maximize Industry 4.0 potential with D4M consultants

In today’s rapidly evolving manufacturing landscape, staying ahead of the curve is crucial. At D4M, we specialize in guiding manufacturing companies through the transition from SAP Manufacturing Execution (ME) and SAP Manufacturing Integration and Intelligence (MII) to SAP Digital Manufacturing (DM). Our comprehensive consultancy services ensure a seamless shift to smarter, more efficient production processes.

At D4M, we are passionate about revolutionizing manufacturing through cutting-edge technology. Our team of experts specializes in helping manufacturing companies transition from SAP ME and SAP MII to the future-ready SAP DM.

Ready to Transform?

Here’s why you should make the move to SAP DM

Why SAP DM is the Smart Choice

Cloud advantage

Say goodbye to on-premises headaches!

SAP DM is cloud-based, offering reduced upfront investment, scalability, and flexibility. It leverages the full potential of the cloud, including Generative AI and Machine Learning. With edge computing and buffering capabilities, SAP DM ensures continuous operation even during cloud outages. It’s like upgrading from a landline to a smartphone—more features, less hassle.

SAP DM Cloud Advantage | Cost-Saving Benefits

Unlike traditional on-premises systems, SAP DM eliminates the need for hefty initial capital expenditures on hardware and infrastructure. This allows you to allocate resources more efficiently.

With SAP DM, maintenance and updates are handled automatically in the cloud, reducing the need for dedicated IT staff and minimizing downtime.

Easily scale your operations up or down based on demand without incurring significant additional costs. This flexibility ensures you only pay for what you need.

Cloud-based solutions often lead to lower energy consumption compared to maintaining on-premises servers, contributing to both cost savings and environmental sustainability.

Real-time data access and advanced analytics enable more efficient decision-making, reducing waste and optimizing resource utilization.

SAP DM Cloud Advantage | Industry Specific Examples

Save on the costs associated with maintaining multiple on-premises systems across different plants by centralizing operations in the cloud.

Reduce compliance-related expenses by leveraging automated updates and robust security features provided by SAP DM.

Lower the costs of managing ingredient sourcing and production schedules through real-time insights and streamlined operations.

Minimize the expenses related to component tracking and machine maintenance with predictive analytics and real-time monitoring.

Cut down on the costs of ensuring regulatory compliance and managing complex production processes with cloud-based tools and real-time data access.

Real-time insights

Want to optimize supply chain management?

SAP Digital Manufacturing (DM) provides crystal-clear, real-time visibility into your manufacturing operations. It’s like having a backstage pass to your production floor, offering actionable insights that enable quick adjustments to production processes.

SAP DM helps you respond to demand fluctuations, supply chain dynamics, and unforeseen disruptions, keeping your manufacturing agile and efficient.

SAP DM Real-Time Insight | Functional Examples

Monitor the progress of production orders in real-time, allowing for immediate intervention if delays occur.

Receive instant alerts on quality issues, enabling swift corrective actions to maintain product standards.

Track inventory in real-time to ensure optimal stock levels and avoid production halts due to material shortages.

Monitor machine health and performance to predict maintenance needs and prevent unexpected downtime.

Gain real-time insights into workforce attendance and shift planning to optimize staffing levels and productivity.

SAP DM Real-Time Insight | Industry Specific Examples

Real-time tracking of assembly line performance and parts availability to ensure timely production and delivery.

Instant monitoring of batch production and quality control to comply with regulatory standards and ensure product safety.

Real-time insights into ingredient usage and production schedules to maintain food safety and meet demand fluctuations.

Continuous monitoring of component usage and machine performance to ensure high-quality production and minimize defects.

Real-time tracking of parts and materials, along with machine health monitoring, to ensure compliance with stringent industry regulations and maintain operational efficiency.

Intuitive interface

Ease of use matters.

SAP Digital Manufacturing (DM) features an intuitive, user-friendly interface designed for efficiency and simplicity. The interface is visually appealing and easy to navigate, ensuring your shop floor team can start working efficiently right away. With customizable dashboards, real-time data visualization, and drag-and-drop functionalities, SAP DM minimizes the learning curve and maximizes productivity.

No more struggling with complex systems—just smooth, seamless operations.

SAP DM Intuitive Interface | Functional Examples

This interface provides a centralized view of all production activities, allowing users to monitor and control processes in real-time. It includes customizable dashboards that display key performance indicators (KPIs) and real-time data, making it easy to identify and address issues quickly.

SAP DM offers digitized job documents and worker guidance, which help reduce costs and increase productivity. These interfaces are designed to be user-friendly, ensuring that workers can easily access and understand the information they need to perform their tasks.

The mobile interface allows users to access SAP DM functionalities on the go. This includes real-time updates on production status, inventory levels, and machine performance, enabling managers and operators to make informed decisions from anywhere.

This interface leverages machine learning to assist with visual inspections. It provides operators with real-time feedback and suggestions, improving the accuracy and efficiency of quality control processes.

The intuitive user interfaces in SAP DM support paperless production by providing digital tools for job tracking, inventory management, and maintenance scheduling. This not only reduces the reliance on physical documents but also streamlines operations and enhances data accuracy.

SAP DM Intuitive Interface | Industry Specific Examples

- Assembly Line Dashboard: Provides real-time tracking of assembly line performance, parts availability, and production status. The interface is designed to be visually intuitive, allowing operators to quickly identify and address any issues.

- Quality Control Interface: Displays real-time data on quality checks and defect rates, enabling immediate corrective actions to maintain high standards.

- Batch Tracking System: Offers a clear and detailed view of batch production processes, including ingredient tracking and compliance checks. The interface ensures that operators can easily monitor and document each step to meet regulatory requirements.

- Regulatory Compliance Dashboard: Provides real-time updates on compliance status, helping ensure that all production processes adhere to industry regulations.

- Ingredient Management Interface: Tracks ingredient usage and inventory levels in real-time, ensuring that production schedules are met without delays. The interface is designed to be user-friendly, with easy access to critical information.

- Production Schedule Dashboard: Displays real-time updates on production schedules, helping managers optimize workflow and respond to demand fluctuations.

- Component Usage Tracker: Monitors the usage of electronic components in real-time, providing insights into inventory levels and potential shortages. The interface is designed to be intuitive, with clear visual indicators for critical metrics.

- Machine Performance Monitor: Provides real-time data on machine health and performance, enabling predictive maintenance and minimizing downtime.

- Parts and Materials Tracking: Offers a detailed view of parts and materials used in production, ensuring traceability and compliance with industry standards. The interface is designed to be easy to navigate, with clear visualizations of key data points.

- Compliance and Safety Dashboard: Displays real-time updates on safety checks and compliance status, helping ensure that all production processes meet stringent industry regulations.

Pre-built applications

Rapid deployment is our mantra.

SAP Digital Manufacturing (DM) comes with pre-built applications, saving you time and effort. Whether you’re in discrete or process industries, SAP DM has you covered. Examples of pre-built applications include these listed below.

These applications ensure quick and efficient implementation without the need for extensive customization.

SAP DM Pre-Built Applications | Functional Examples

Streamline the creation, scheduling, and tracking of production orders.

Monitor and control quality processes to ensure product standards.

Efficiently manage inventory levels and material flow.

Schedule and track maintenance activities to minimize downtime.

Gain insights into production performance with real-time data visualization.

SAP DM Pre-Built Applications | Industry Specific Benefits

Manage assembly lines, track parts, and ensure compliance with industry standards, leading to improved efficiency and reduced production costs.

Ensure regulatory compliance, batch tracking, and quality control, which are critical for meeting stringent industry requirements and maintaining product safety.

Manage production schedules, ensure food safety, and track ingredient sourcing, helping to maintain high standards of quality and compliance with health regulations.

Handle complex supply chains, track component usage, and ensure product quality, which is essential for maintaining reliability and customer satisfaction.

Manage detailed production processes, track parts and materials, and ensure compliance with industry regulations, leading to enhanced safety and operational efficiency.

Extensive analytic capability

SAP Digital Manufacturing (DM) enhances the capabilities of SAP ME and SAP MII by integrating advanced analytics and machine learning.

With SAP DM, you don’t just track production orders; you gain deep insights and actionable intelligence. It’s like upgrading from a basic compass to a GPS for your manufacturing operations, enabling smarter decision-making with Generative AI and Machine Learning.

SAP DM Extensive Analytic Capabilities | Functionality Examples

Customizable dashboards provide real-time insights into key performance indicators, helping you monitor and optimize production efficiency, machine utilization, and quality metrics.

Example: SAP DM provides customizable KPI dashboards that offer real-time insights into key performance indicators such as production efficiency, machine utilization, and quality metrics. These dashboards allow users to quickly identify trends and make data-driven decisions

Explore data at various levels of detail to identify bottlenecks and areas for improvement, from high-level overviews to specific production lines or shifts.

Example: Users can create drilldown reports that allow them to explore data at various levels of detail. For instance, a production manager can start with a high-level view of overall production performance and then drill down into specific production lines or shifts to identify bottlenecks.

Leverage machine learning to predict equipment failures and perform proactive maintenance, reducing downtime and improving operational reliability.

Example: SAP DM leverages machine learning to provide predictive analytics. For example, it can predict equipment failures based on historical data and sensor readings, allowing maintenance teams to perform proactive maintenance and reduce downtime.

Track defect rates and inspection results in real-time to ensure products meet quality standards and identify opportunities for process improvements.

Example: Real-time quality management reports track defect rates, inspection results, and compliance with quality standards. These reports help ensure that products meet quality requirements and identify areas for improvement.

Optimize inventory management and supply chain performance with detailed reports on material usage and supply chain dynamics.

Example: SAP DM offers detailed reports on inventory levels, material usage, and supply chain performance. These reports help optimize inventory management, reduce waste, and improve supply chain efficiency.

Maintain production schedules and meet delivery deadlines with real-time updates on production order status.

Example: Reports on production order status provide real-time updates on the progress of production orders, including any delays or issues. This helps in maintaining production schedules and meeting delivery deadlines.

SAP DM Extensive Analytic Capabilities | Industry Specific Examples

Production Efficiency Reports: Track assembly line performance, identify bottlenecks, and optimize production schedules to improve efficiency.

Quality Control Dashboards: Monitor defect rates and inspection results in real-time to ensure high-quality standards and reduce rework.

Batch Production Analysis: Detailed reports on batch production processes, including compliance with regulatory standards and quality control metrics.

Supply Chain Analytics: Real-time visibility into supply chain performance, helping to manage inventory levels and ensure timely delivery of raw materials.

Ingredient Usage Reports: Track ingredient usage and inventory levels to optimize production schedules and reduce waste.

Production Schedule Dashboards: Real-time updates on production schedules, helping to meet demand fluctuations and maintain food safety standards.

Component Usage Tracking: Monitor the usage of electronic components in real-time to ensure optimal inventory levels and minimize production delays.

Machine Performance Reports: Detailed analysis of machine health and performance, enabling predictive maintenance and reducing downtime.

Parts and Materials Tracking: Real-time tracking of parts and materials used in production, ensuring traceability and compliance with industry standards.

Compliance and Safety Dashboards: Monitor safety checks and compliance status in real-time to ensure adherence to stringent industry regulations.

- Swiftly adapt to market shifts and customer demands.

- Meet market-of-one demand, handle extreme product variability, improve customer satisfaction, and maintain productivity, margins, and quality levels

- Implement robust quality control and predictive maintenance.

- Empower key stakeholders to analyze global and plant-level manufacturing performance and associated causes through intuitive, preconfigured analytics.

- Acquire data from different manufacturing operations management (MOM) and automation systems by uniting multiple solutions and standards-based interfaces.

- Facilitate continuous business improvement by accelerating root-cause analysis with advanced algorithms and machine learning.

- Leverage data analytics and process optimization for streamlined operations.

- Seamlessly expand as your business grows.

- Support better, more transparent production management to assess and resolve quality and productivity issues quickly while reducing warranty and liability risk

- Reduce IT and maintenance expenses through cloud infrastructure.

- Keep MOM systems running smoothly by optimizing the use of manufacturing resources, improving quality, and minimizing downtime.

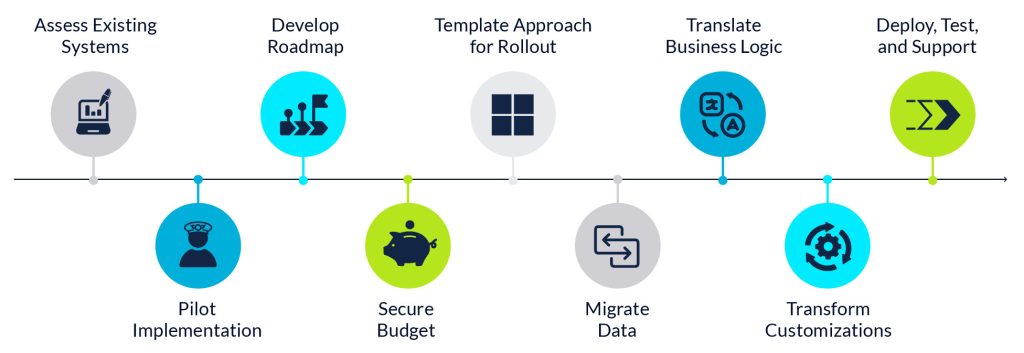

Implementing SAP digital manufacturing: a step-by-step guide

Your Solutions Partner. How We Empower You.

Our Committment

At D4M, our passion lies in revolutionizing manufacturing through cutting-edge technology. Our expert team specializes in empowering manufacturing companies to embrace the future with confidence.

Guided Transformation

We tailor SAP DM strategies to your unique manufacturing environment, ensuring a seamless transition.

Hands-On Implementation

From initial setup to fine-tuning, we’re with you every step of the way. Let’s turn your vision into reality.

Empowering Your Team

Equip your workforce with comprehensive training programs, empowering them to maximize SAP DM benefits.

Reliable Support

Count on us for ongoing assistance – whether it’s troubleshooting, upgrades, or optimizing operations.